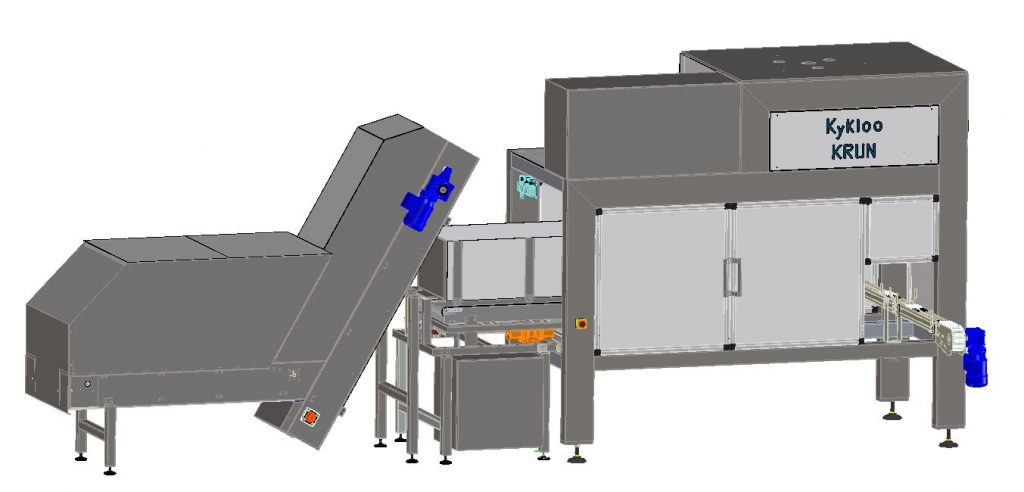

Krun 1

- The KRUN 1 unscrambling system does not require any “changeover” components.

- A feeding system attached to a conveyor guarantees a constant flow of containers to the handling unit.

- An automated system pre-orders the different bottles arriving from an elevator and prepares them for a vision control system.

- A camera continuously captures images of the containers for the robotic handling system, which either reorders them or deposits them in a stabilisation system before they are released onto the customer’s belt.

- The system does not require recirculation of the bottles as it is designed to pick up 100% of the incoming product.

- Extremely compact footprint

- No constraints on programming new formats, even by the customer

- Remote control for timely assistance

- Suitable for medium and low speeds for bottles to be oriented